Our aircraft cabinetry table hinges are made from 416 stainless steel and do not fail when used properly. These patented drop-leaf table hinges use a double pivot-point principle which ensures that the table leaves do not bind when being opened or stowed. An installed spring times the rotation so that one leaf rotates 90 degrees around one pivot point, then the leaf moves an additional 90 degrees against the spring-loaded pivot point. This timed rotation provides for a smooth table hinge operation and makes the Morgan stainless steel hinges the “strongest hinges in the world”.

Our two most recent drop-leaf table hinges are the BFH-45S-180K and the BFH-4S-200/225K (the BFH-4S-200/225K is being phased out). Both hinges allow the user to install two panels with a virtual “butt-fit”. Both hinges have the same rating as the HCTH-4S-180 hinge. The picture below shows a demonstrator with a BFH-4S-200/225K Hinge Kit lying on top and a BFH-45S-180K Hinge Kit lying on bottom. Click on either hinge for a larger view. Both hinges fit into a 1/2″ panel; however, the BFH-45S-180K is slightly thinner than the BFH-4S-200/225K.

Below is a picture of the HCTH-4S-180 lying on top of two table leaves. Also depicted are four LM-10/32-2.2 leg mounts which are commonly used to aid in installing the hinge.

The HCTH-4S-180 hinge fits into a 1/2 ” or larger panel. We manufacture hinges for other sized table leaves ranging from 1/4″ to over 5/8″ in thickness. Some of those drop-leaf table hinges, their ratings and appropriate panel thicknesses are depicted in the table below. For a description of load testing procedures, click here.

| Hinge | Panel Thickness | Sustained Weight |

| HCTH-2S-180 Family | For 1/4″ or thicker panels | 257 inch/pounds |

| HCTH-3S-180 Family | For 3/8″ or thicker panels | 523 inch/pounds |

| HCTH-44S-180 Family | For 1/2″ or thicker panels | 263 inch/pounds |

| HCTH-4S-180 Family | For 1/2″ or thicker panels | 523 inch/pounds |

| HCTH-5S-180 Family | For 5/8″ or thicker panels | 823 inch/pounds |

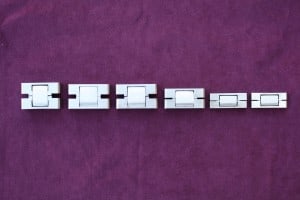

The picture below depicts several HCTH-style hinges from our largest to smallest. Shown from the left to right are the HCTH-5S-180, the HCTH-4S-180, the HCTH-44S-180, the HCTH-3S-180, the HCTH-2S-180 (it has square cornered side frames) and the HCTH-2S-180RC.

The HCTH-4S-180 hinge has been our best seller and in response to aircraft cabinetry customers’ requests comes with different springs and other modifications. The HCTH-4S-180 hinge has a LH 0.028 left-hand wound spring, which tends to keep the leaf in the open position. The HCTH-4SR-180 hinge has a RH 0.028 right-hand wound spring, which tends to keep the leaf in the closed or stowed position. The HCTH-4S-180H hinge has a heavier left-hand wound spring (LH 0.031) and the HCTH-4S-180L hinge has a lighter left-hand wound spring (LH 0.024). These larger and smaller diameter springs can be used to achieve customer-desired results.

If a customer plans to plate a portion of the hinge, it is necessary to install the spring after plating has been completed. Since it is far easier to install a new spring (one that does not have its “tail” snipped after installation) than one installed by us prior to shipment, some customers will ask that the hinge be shipped with a loose spring.

Finally, some customers prefer using a slightly thinner hinge for 1/2″ applications. Our HCTH-4S-180 hinge is 0.480″ thick. We also have a thinner version of this hinge, the HCTH-44S-180, which is 0.440″ thick. It functions the same as the HCTH-4S-180.